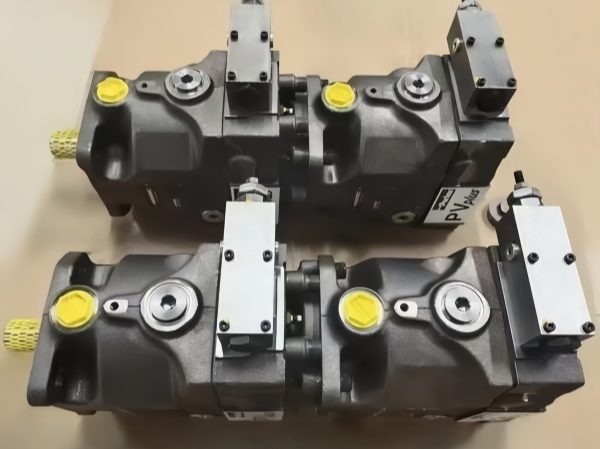

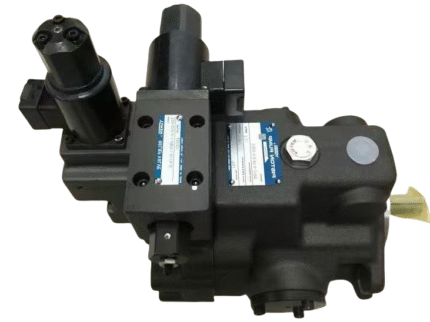

Parker PV series plunger pump

$399.00

Parker plunger pump PV046R1K1T1NMMC: 46 cc/rev displacement, pressure compensated control, suitable for medium flow systems.PV180R1K1T1NFFC: displacement 180 cc/rev, electric proportional control, suitable for high-precision automation equipment.

Parker PV series variable displacement plunger pump is the core component in the industrial hydraulic field. It is widely used in injection molding machine, engineering machinery, ship hydraulic system and other scenes with its high efficiency, high reliability and modular design.

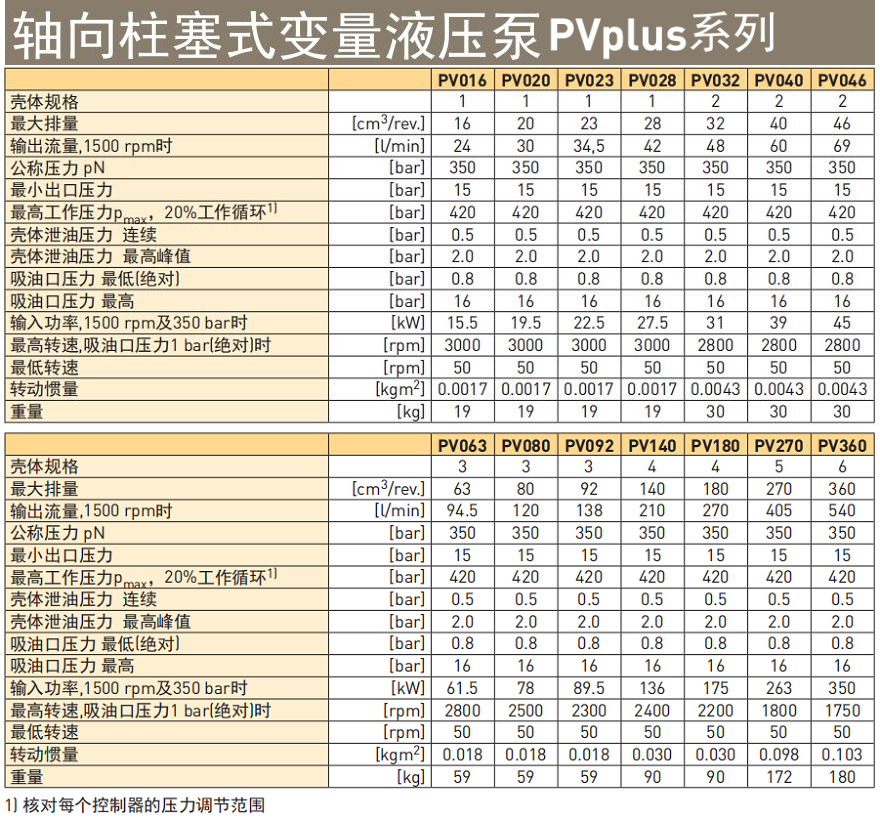

1、 Core specification parameters

Range of displacement

Standard displacement: 8, 11, 16, 21, 23, 25, 27, 32, 38, 45, 53, 60, 68, 76, 90, 100, 107, 125, 140, 180, 200, 250 cm ³/rev

Customized displacement: non-standard displacement of 5~500 cm ³/rev can be provided to meet special needs (such as ultra-small flow or ultra-large flow system).

Displacement accuracy: ± 2% (ISO 9110 compliant) for flow stability.

Pressure rating

Rated pressure: 28 MPa (continuous operation, service life ≥ 10000 hours)

Peak pressure: 35 MPa (short-term allowable, ≤ 1 minute, applicable to impact load scenario)

Low voltage starting pressure: ≤ 0.5 MPa (excellent no-load starting characteristics and reduced motor starting current).

Speed range

Minimum speed: 300 rpm (ensure the oil viscosity ≥ 10 cSt to avoid insufficient lubrication)

Rated speed: 1800 rpm (continuous operation, volume efficiency ≥ 95%)

Maximum speed: 3000 rpm (short-term allowable, enhanced lubrication and cooling required, e.g. increased oil flow).

Performance index

Volumetric efficiency: ≥ 95% (rated condition, ISO 4406 18/16/13 cleanliness)

Overall efficiency: ≥ 90% (rated working condition, mechanical efficiency ≥ 95%)

Noise level: ≤ 72 dB (A) (1m distance, rated speed, complying with ISO 3744 standard)

Service life: design service life ≥ 10000 hours (continuous operation, oil cleanliness up to standard).

Parker PV series

2、 Control mode and function

Pressure compensation variable control (R1/R2)

Principle: Adjust the pump displacement through the spring and pressure signal to keep the outlet pressure constant.

R1: Standard pressure compensation, applicable to single pump system (such as injection molding machine clamping).

R2: remote pressure compensation, external pressure signal source, applicable to multi-pump parallel system (such as die lock of die casting machine).

Response time: ≤ 50 ms (displacement adjustment speed when pressure changes).

Flow compensation variable control (K1/K2)

Principle: Adjust the displacement through the feedback of flow sensor to keep the outlet flow constant.

K1: Standard flow compensation for constant flow demand scenarios (e.g. NC machine feed).

K2: Flow compensation with pressure priority, which preferentially meets system pressure requirements (such as test bench loading).

Flow accuracy: ± 1% (steady state condition).

Load sensitive control (LS)

Principle: Adjust the pump displacement through the load pressure signal to achieve demand-based oil supply, with obvious energy saving effect.

Application scenario: systems with frequent load changes such as walking motor of engineering machinery and luffing mechanism of crane.

Energy saving effect: it can reduce energy consumption by 20%~30% compared with the constant displacement pump.

Electric variable control (E1/E2)

E1: 4-20 mA electric signal control displacement, response time ≤ 50 ms, applicable to analog control scenario (such as hydraulic press).

E2: CAN bus communication control, supporting linkage with PLC or industrial computer, realizing digital hydraulic system (such as intelligent production line).

Communication protocol: support CANopen, Profibus-DP and other industrial buses.

parker piston pump

Parturient ut id tellus vulputatre ac ultrlices a part ouriesnt sapien dignissim partu rient a a inter drum vehicula. Ornare metus laoreet tincidunt eros rolem tristique pretium malada.

Cras rhoncus vivamus luctus platea arcu laoreet selm. Curae est condenectus sed hac a parturient vestibulum.

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

评价

目前还没有评价